PORTFOLIO

KeepStock Managed

SITUATION

Facilities seeking external help with management of MRO inventory were limited to two options in the marketplace, each with drawbacks:

- VMI = Vendor managed inventory by the material supplier at no charge but restricted to only that supplier’s products (i.e., an incomplete solution).

- Integrated Supply = Total management of MRO supply chain that required transfer of procurement function as well (i.e., an exorbitant solution).

Grainger sought to fill this gap to meet the needs of large and complex customers who requested management of non-Grainger materials but were uninterested in partnering with an integrated supplier.

WORK COMPLETED

A staff-augmentation offer was developed to enable customers to obtain help incrementally and bring MRO material management and sourcing expertise into their existing storeroom operations. My work over the course of the development project and initial go to market spanned all aspects of a new product launch, including:

- Creation of core narrative, value proposition, positioning and messaging.

- Design of entire sales cycle process, spanning lead submission and qualification, opportunity assessment, proposal creation, contract authoring and service implementation.

- Development of sales enablement materials, including talk tracts, pitch decks, conversation guides, customer profiles and discovery questions.

- Collaboration with marketing to produce collateral such as one pagers, brochures, capabilities overview, etc.

- Design of 40’ x 40’ tradeshow booth.

OUTCOME

KS Managed was deemed operational and transitioned to a full-time program manager after a two year development and launch cycle.

During that time customers who implemented KS Managed increased annual product purchases by 155% on average. In addition, operating expenses for KS Managed implementations proved to be 48% lower than similarly staffed implementations of Grainger’s VMI solution.

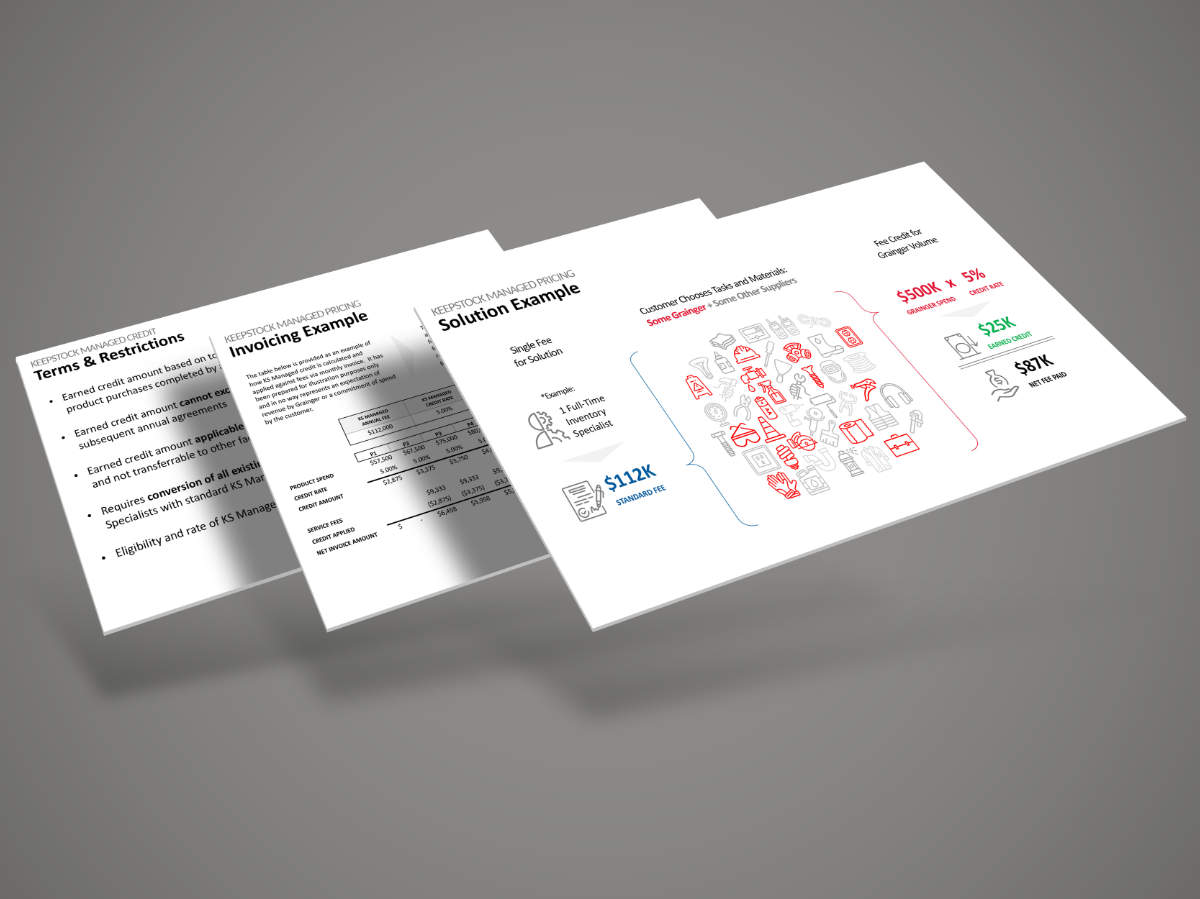

A sampling of deliverables and marketing assets created during the project are pictured below.